Chambers of retarded-proving and conservation of the fermented product for bread.

- Operating temperature: -12 / +40°C

- Relative humidity: 75 ÷ 95%

- Control panel: MICRO C10 1.5

- Option: PRO-10 TS touch screen

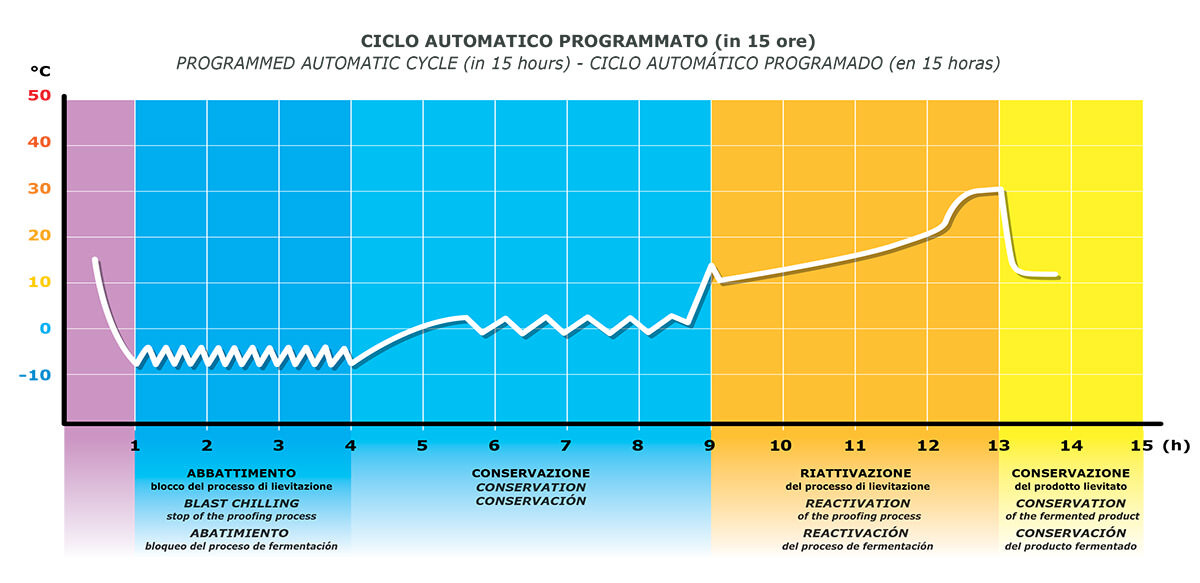

The ‘retarded-proving’ is a programmed automatic process for the fermentation of bread and pastry doughs in the desired time.

Both our MICRO C10 1.5 and PRO-10 TS touch screen control panel assure the proofing (also called proving) process management with the complete control of times, temperature and humidity during the different working stages.

Chambers of retarded-proving and conservation of the fermented product for bread.

Cabinets and chambers of retarded-proving and conservation of the fermented product for pastry.

Chambers of retarded-proving and conservation of the fermented product for bread and pastry.

Chambers of direct proving (or proofing) > heat & humidity only

We and selected third parties use cookies or similar technologies for technical purposes and, with your consent, also for other purposes as specified in the cookie policy. If you close this banner by ticking or clicking on "Decline", only technical cookies will be used. If you want to select the cookies to be installed, click on "Customize". If you prefer, you can consent to the use of all cookies, including those other than technical, by clicking on "Accept all". You can change your choice at any time.